High Performance T53 Engine & Component Overhaul

MRO for the T53 Series Engine Fuel Controls and Components

Air Technology Engines(ATE) is improving the reliability and performance of T53 engines.

Engines are built to tighter tolerances, improving combustion efficiency and optimizing engine performance. New repairs and performance enhancements are a top priority.

The T53 engine has become more expensive to repair because of excessive erosion of the 1st stage gas produce blades and nozzle in the T5317/703 series engines.

Approximately 60% of the engines require replacement of these components costing over $175,000. To solve this problem, Our engineers reviewed the airflow of the combustion liner and designed a special repair.

Air Technology Engines(ATE) is improving the reliability and performance of T53 engines.

Engines are built to tighter tolerances, improving combustion efficiency and optimizing engine performance. New repairs and performance enhancements are a top priority.

The T53 engine has become more expensive to repair because of excessive erosion of the 1st stage gas produce blades and nozzle in the T5317/703 series engines.

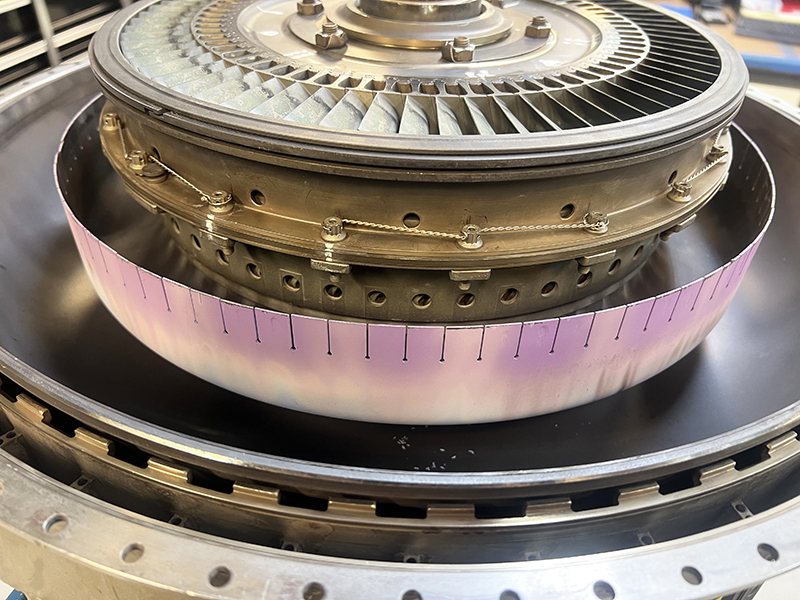

Approximately 60% of the engines require replacement of these components costing over $175,000. To solve this problem, Our engineers reviewed the airflow of the combustion liner and designed a special repair. Major Improvement of Combustion Liner

Extensive testing in 2023 established measurable performance improvements as compared to the current configuration. ATE received FAA approval to repair the Combustion Liner that improves the efficiency of combustion, and improves cooling of the 1st stage gas producer blade tips. Testing established that the 1st stage GP blades have additional cooling by 130 degrees F. Airflow to the 1st stage blades and nozzle increase from 130 mph to 300 mph. The test engine had 3% reduction in fuel burn.

This repaired liner improves fuel efficiency and reduces the damage caused by unburned fuel particles (carbon ball blasting.) Operators may receive the combustion liner during mid life inspection and overhaul.

Extensive testing in 2023 established measurable performance improvements as compared to the current configuration. ATE received FAA approval to repair the Combustion Liner that improves the efficiency of combustion, and improves cooling of the 1st stage gas producer blade tips. Testing established that the 1st stage GP blades have additional cooling by 130 degrees F. Airflow to the 1st stage blades and nozzle increase from 130 mph to 300 mph. The test engine had 3% reduction in fuel burn.

This repaired liner improves fuel efficiency and reduces the damage caused by unburned fuel particles (carbon ball blasting.) Operators may receive the combustion liner during mid life inspection and overhaul. Air Technology Engines has obtained many special repairs for T53 parts from Factory and the FAA. Many have become service bulletins, supporting improved reliability and reduced cost.

Strong engineering support is essential to building better performing engines. Air Technology's team includes the former Project Manager for the development and production of the T53 engine in Lycoming. Our engines incorporate engineering improvements that increase engine performance and reliability. ATE consistently produces engines with excellent temperature margins of 90 to 120 degrees F.

© Copyright all rights reserved Air Technology Engines, Inc.Site by: Exploritech, Inc.